Maximizing Efficiency Diesel Generators for Inductive Loads

Introduction

Diesel generators play a crucial role in providing a reliable and constant power supply in various applications, especially when it comes to powering inductive loads. Inductive loads, such as motors, compressors, and transformers, require a steady and stable power source to function efficiently. In this article, we will explore the importance of diesel generators for inductive loads, their working principles, key considerations for optimal performance, and best practices for maximizing efficiency.

Understanding Inductive Loads

Before delving into the specifics of diesel generators, it is essential to understand the nature of inductive loads and why they require special consideration. Inductive loads are devices that rely on electromagnetic induction to operate, such as electric motors and transformers. Unlike resistive loads, which consume power instantaneously, inductive loads exhibit a lag in power consumption due to the magnetic field buildup.

When an inductive load is connected to a power source, it draws both active power (real power) and reactive power. The active power is responsible for performing the actual work, while the reactive power is required to establish and maintain the magnetic field within the device. This reactive power results in a phase shift between the voltage and current waveforms, leading to a power factor less than unity.

The presence of inductive loads in electrical systems can cause several challenges, including voltage fluctuations, power factor issues, and increased energy consumption. To ensure 200kw diesel generator for telecommunications and efficient operation of inductive loads, it is crucial to have a stable and robust power supply, which is where diesel generators come into play.

Diesel Generators for Inductive Loads: Working Principles

Diesel generators are a popular choice for powering inductive loads due to their reliability, durability, and ability to provide continuous power output. Unlike grid power, which may be prone to interruptions and voltage fluctuations, diesel generators offer a dependable source of backup power that can handle the dynamic requirements of inductive loads.

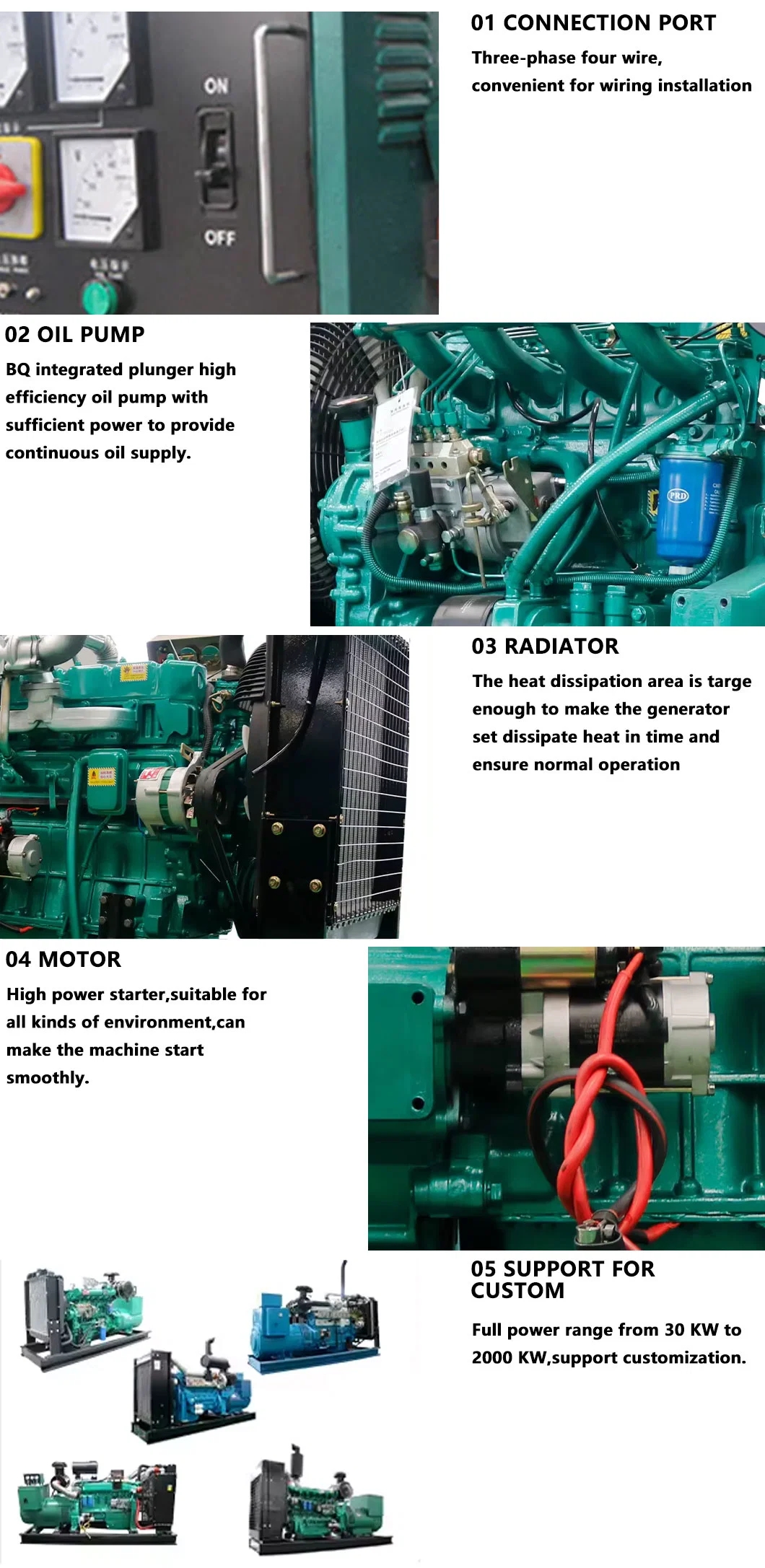

The working principle of a diesel generator involves converting the chemical energy stored in diesel fuel into mechanical energy through combustion. This mechanical energy is then converted into electrical energy using an alternator or generator. The generated electricity is typically in the form of alternating current (AC), which is suitable for powering a wide range of electrical devices, including inductive loads.

When connected to inductive loads, diesel generators must be capable of handling the transient and steady-state power requirements of these devices. Inductive loads, such as motors, exhibit high starting currents known as inrush currents, which can put a strain on the generator if not properly managed. Diesel generators designed for inductive loads are equipped with features such as robust alternators, voltage regulators, and overload protection to ensure smooth operation under varying load conditions.

Key Considerations for Optimal Performance

To maximize the efficiency and reliability of diesel generators when powering inductive loads, several key considerations must be taken into account:

1. Sizing and Capacity: Properly sizing the diesel generator to match the power requirements of the inductive loads is essential for optimal performance. Oversized generators can lead to inefficient operation and increased fuel consumption, while undersized generators may struggle to meet the load demands, resulting in voltage fluctuations and potential damage to equipment.

2. Power Factor Correction: In applications where inductive loads are predominant, power factor correction is crucial to minimize reactive power consumption and improve overall system efficiency. Diesel generators equipped with power factor correction capabilities can adjust the voltage and current waveforms to achieve a unity power factor, reducing energy losses and improving voltage stability.

3. Voltage Regulation: Maintaining stable voltage output is critical when powering inductive loads to prevent voltage sags or surges that can affect equipment performance. Diesel generators with advanced voltage regulation systems ensure a consistent supply of electricity under varying load conditions, mitigating the risk of voltage-related issues.

4. Load Management: Effective load management is key to optimizing the performance of diesel generators for inductive loads. By monitoring and controlling the distribution of power to different loads, generators can operate more efficiently and prevent overloading or underloading conditions that can compromise system reliability.

5. Maintenance and Servicing: Regular maintenance and servicing of diesel generators are essential to ensure their long-term performance and reliability. Periodic inspections, oil changes, filter replacements, and testing of critical components help identify potential issues early and prevent unexpected downtime.

Best Practices for Maximizing Efficiency

In addition to the key considerations outlined above, several best practices can help maximize the efficiency of diesel generators for inductive loads:

1. Proper Installation: Diesel generators should be installed in a well-ventilated and secure location to ensure optimal performance and safety. Adequate clearance around the generator for air circulation, proper grounding, and compliance with local regulations are essential for a successful installation.

2. Fuel Quality and Storage: Using high-quality diesel fuel and ensuring proper storage conditions are critical for maintaining the efficiency of the generator. Contaminated or degraded fuel can lead to engine issues and reduced performance, emphasizing the importance of regular fuel testing and treatment.

3. Remote Monitoring and Control: Implementing remote monitoring and control systems allows operators to track the performance of the generator in real time, identify potential issues, and make adjustments as needed. Remote access to critical parameters such as fuel levels, temperature, and load status enhances operational efficiency and minimizes downtime.

4. Training and Education: Providing comprehensive training to operators and maintenance staff on the proper operation and maintenance of diesel generators is essential for maximizing efficiency. Knowledge of best practices, troubleshooting techniques, and safety protocols ensures the safe and effective use of the equipment.

5. Environmental Considerations: Diesel generators can have a significant environmental impact due to emissions and fuel consumption. Implementing eco-friendly practices such as using biodiesel blends, optimizing load sharing among multiple generators, and adhering to emissions regulations can help minimize the environmental footprint of diesel generator operations.

Conclusion

Diesel generators play a critical role in powering inductive loads across various industries, providing a reliable and efficient source of backup power. By understanding the working principles of diesel generators, considering key factors for optimal performance, and implementing best practices for efficiency, operators can ensure the seamless operation of inductive loads with minimal downtime and energy waste.

As technology continues to advance, the integration of smart features, remote monitoring capabilities, and eco-friendly solutions will further enhance the efficiency and sustainability of diesel generators for inductive loads. By staying informed and proactive in adopting best practices, operators can maximize the performance and longevity of their generator systems, ultimately contributing to a more reliable and resilient power supply for critical applications.